Product Detail:

Chemical Composition

| Alloy | element | C | Si | Mn | S | Ni | Cr | Al | Ti | Fe | Cu |

| MonelK

500 |

Min | 63.0 | 2.3 | 0.35 | 27.0 | ||||||

| Max | 0.25 | 0.5 | 1.5 | 0.01 | 3.15 | 0.85 | 2.0 | 33.0 |

Mechanical Properties

| Alloy Status | Tensile strength Rm Mpa |

| annealed | 645 |

| Solution& precipitation | 1052 |

Physical Properties

| Density g/cm3 | Melting Point ℃ |

| 8.44 | 1315~1350 |

Standard

Rod, Bar, Wire and Forging Stock – ASTM B 865 (Rod and Bar)

Plate, Sheet and Strip – BS3072NA18 (Sheet and Plate), BS3073NA18 (Strip),

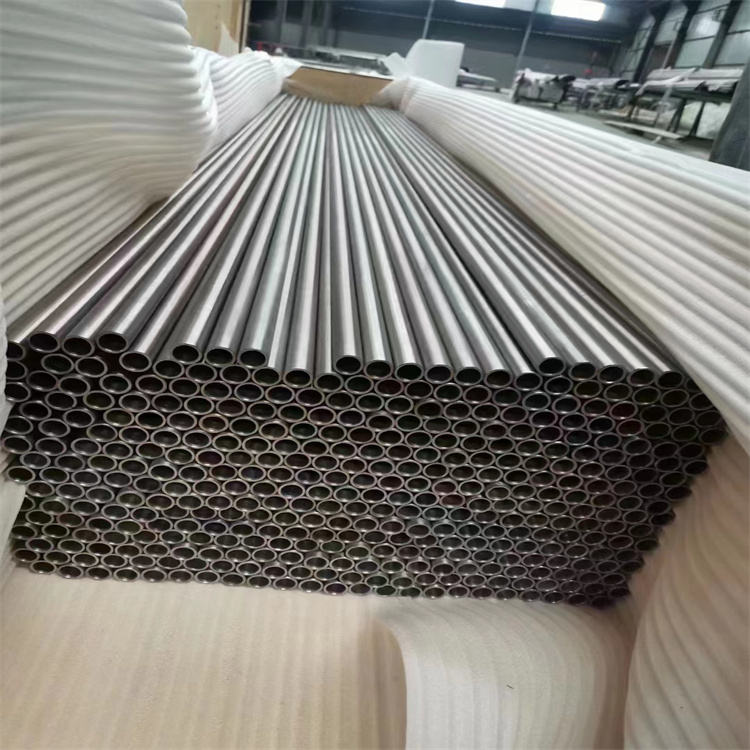

Pipe & Tube – BS3074NA18

Characteristics of Monel K500

- Corrosion resistance in an extensive range of marine and chemical environments. From pure water to non-oxidizing mineral acids, salts and alkalis.

- Excellent resistance to high velocity sea water

- Resistant to a sour-gas environment

- Excellent mechanical properties from sub-zero temperatures up to about 480C

- Non-magnetic alloy