Product Detail:

Chemical Composition

|

Alloy |

element | C | Si | Mn | S | Cu | Al | Cr | Ni | Ti | Fe | Mo |

|

Nickel 825 |

Min |

1.5 |

19.5 |

38.0 |

0.6 |

22.0 |

2.5 |

|||||

| Max | 0.05 | 0.5 | 1.0 | 0.03 | 3.0 | 0.2 | 23.5 | 46.0 | 1.2 |

3.5 |

Mechanical Properties

|

Alloy Status |

Tensile strength Rm Min Mpa | Yield strength R P 0. 2 Min Mpa | Elongation |

| annealed | 590 | 260 |

30 |

Physical Properties

|

Density g/cm3 |

Melting Point ℃ |

| 8.2 |

1370~1400 |

Standard

Rod, Bar, Wire and Forging Stock – ASTM B 164 (Rod, Bar, and Wire),ASTM B 564 (Forgings)

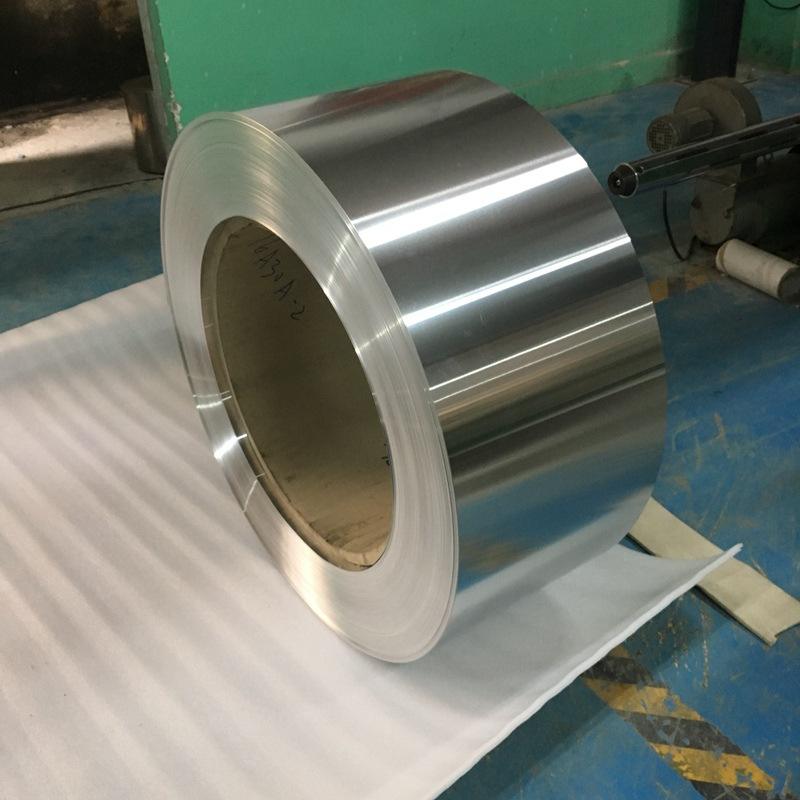

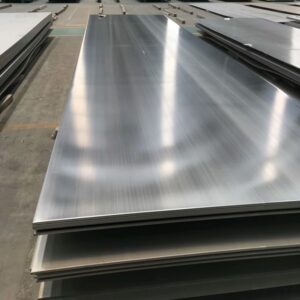

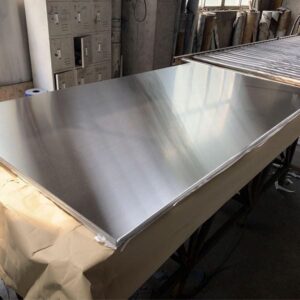

Plate, Sheet and Strip -,ASTM B 127, ASME SB 127

Pipe & Tube – ASTM B 165(Seamless Pipe and Tube), ASTM B 725 (Welded Pipe), ASTM B 730 (Welded Tube), ASTM B 751 (Welded Tube), ASTM B 775 (Welded Pipe), ASTM B 829(Seamless Pipe and Tube)

Welding Products – Filler Metal 60-AWS A5.14/ERNiCu-7;Welding Electrode 190-AWS A5.11/ENiCu-7.

Characteristics of Nickel 825

- Maintain good stability under high temperature and pressure

- Nickel 825 also offers excellent weldability and workability

- It has excellent corrosion resistance, high temperature and high pressure stability, good weldability and processability