Product Detail:

Chemical Composition

| Alloy | element | C | Si | Mn | S | Co | Fe | Al | Cr | Ni | Mo | P | Nb |

| Nickel 625 | Min | 20.0 | 58.0 | 8.0 | 3.15 | ||||||||

| Max | 0.1 | 0.5 | 0.5 | 0.015 | 1.0 | 5.0 | 0.4 | 23.0 | 10.0 | 0.015 | 4.15 |

Mechanical Properties

| Alloy Status | Tensile strength Rm Min Mpa | Yield strength R P 0. 2 Min Mpa | Elongation |

| annealed | 760 | 345 | 30 |

Physical Properties

| Density g/cm3 | Melting Point ℃ |

| 8.4 | 1290-1350 |

Standard

Rod, Bar, Wire and Forging Stock – ASTM B 164 (Rod, Bar, and Wire),ASTM B 564 (Forgings)

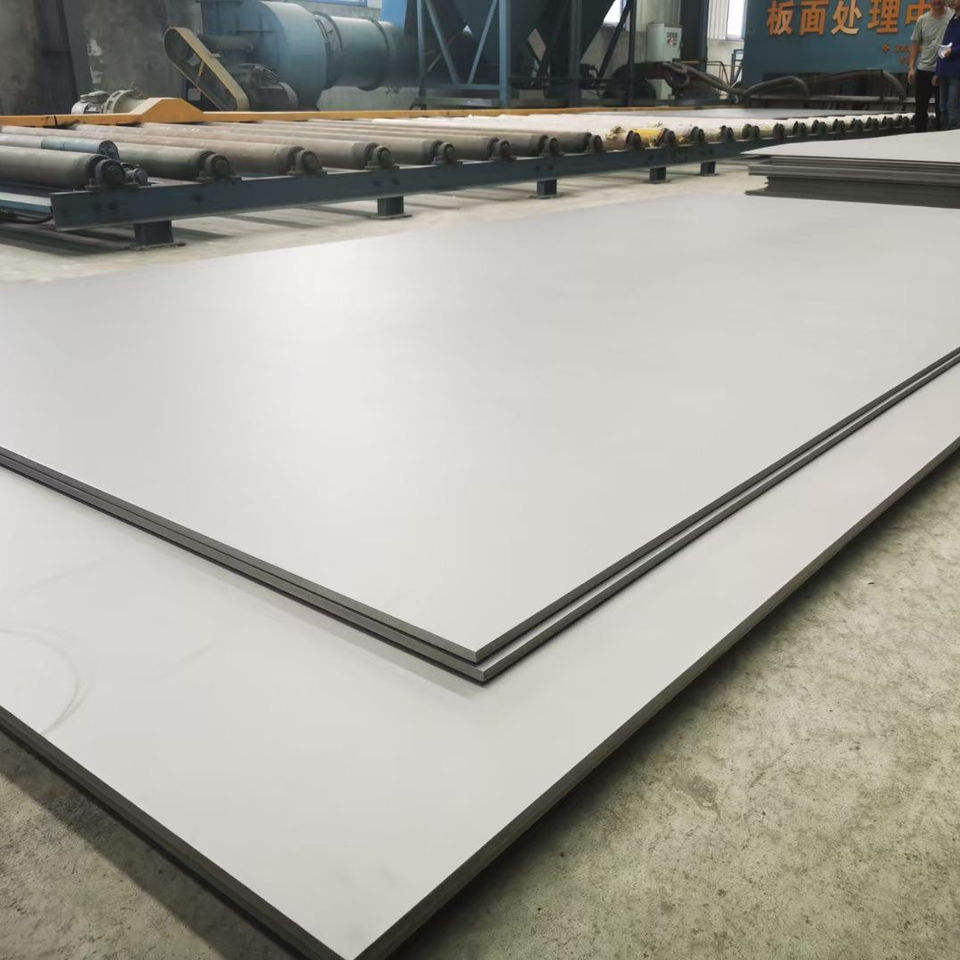

Plate, Sheet and Strip -,ASTM B 127, ASME SB 127

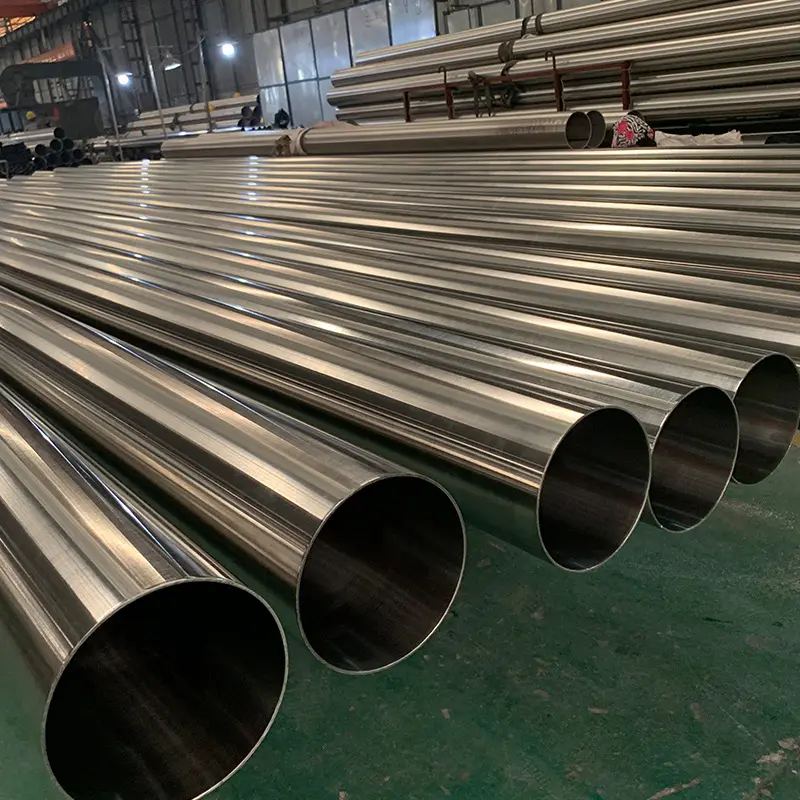

Pipe & Tube – ASTM B 165(Seamless Pipe and Tube), ASTM B 725 (Welded Pipe), ASTM B 730 (Welded Tube), ASTM B 751 (Welded Tube), ASTM B 775 (Welded Pipe), ASTM B 829(Seamless Pipe and Tube)

Welding Products – Filler Metal 60-AWS A5.14/ERNiCu-7;Welding Electrode 190-AWS A5.11/ENiCu-7.

Characteristics of Nickel 625

- Good strength and ductility over a temperature range from below zero to over 980°C

- Excellent corrosion and fatigue resistance in a wide range of corrosive environments, including seawater and industrial acids

- Non-magnetic and fire-resistant

- Can withstand high temperature oxidation and carbonization

- Excellent resistance to stress corrosion cracking