Product Detail:

Chemical Composition

| Alloy | element | C | Si | Mn | S | Fe | Cr | Ni | Ti | Fe | Mo | Cu | P | Nb |

| Nickel

617 |

Min | 20.0 | 44.5 | 8.0 | 0.6 | |||||||||

| Max | 0.1 | 0.5 | 0.5 | 0.015 | 3.0 | 24.0 | 56.0 | 0.6 | 3.0 | 10.0 | 0.5 | 0.015 | 1.5 |

Mechanical Properties

| Alloy Status | Tensile strength Rm Min Mpa | Yield strength R P 0. 2 Min Mpa | Elongation |

| annealed | 680 | 300 | 30 |

Physical Properties

| Density g/cm3 | Melting Point ℃ |

| 8.4 | 1330-1380 |

Standard

Rod, Bar, Wire and Forging Stock – ASTM B 164 (Rod, Bar, and Wire),ASTM B 564 (Forgings)

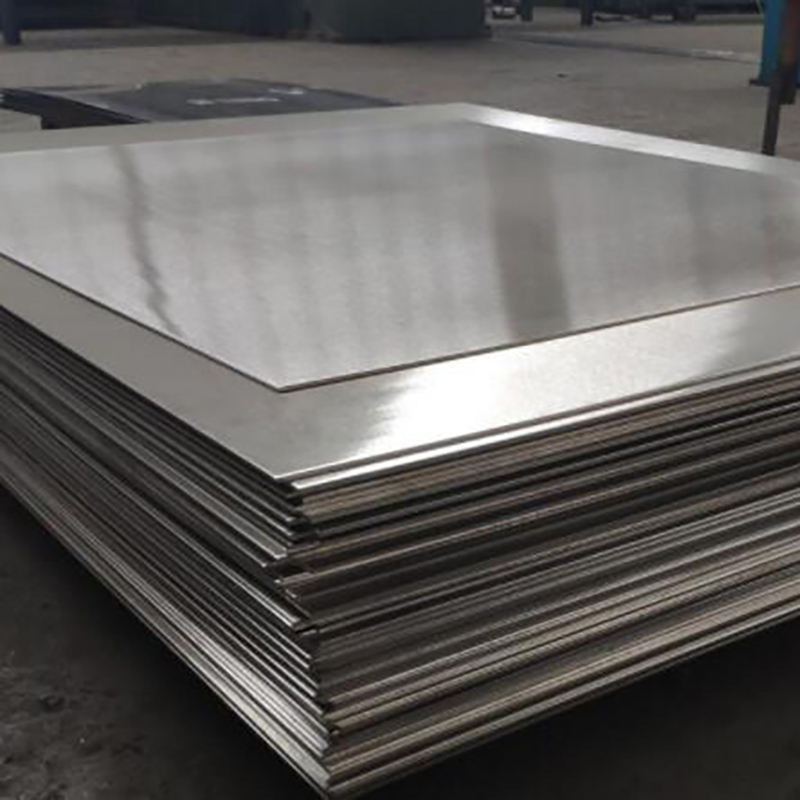

Plate, Sheet and Strip -,ASTM B 127, ASME SB 127

Pipe & Tube – ASTM B 165(Seamless Pipe and Tube), ASTM B 725 (Welded Pipe), ASTM B 730 (Welded Tube), ASTM B 751 (Welded Tube), ASTM B 775 (Welded Pipe), ASTM B 829(Seamless Pipe and Tube)

Welding Products – Filler Metal 60-AWS A5.14/ERNiCu-7;Welding Electrode 190-AWS A5.11/ENiCu-7.

Characteristics of Nickel 617

- It has good instantaneous and long-term mechanical properties at high temperatures up to 1100℃.

- High oxidation resistance at 1100℃.

- High carbonization resistance at 1100℃.

- good welding performance.