Product Detail:

Chemical Composition

| Alloy | element | Si | Mn | S | Ni | Fe | Cu | C | Cr | Ti | Al |

| Nickel 600 | Min | 6.0 | 14.0 | ||||||||

| Max | 0.5 | 1.0 | 0.02 | 99.0 | 10.0 | 0.5 | 0.15 | 17.0 | 0.3 | 0.3 |

Mechanical Properties

| Alloy Status | Tensile strength Rm Min Mpa | Yield strength R P 0. 2 Min Mpa |

| annealed | 390 | 115 |

Physical Properties

| Density g/cm3 | Melting Point ℃ |

| 8.47 | 1350-1400 |

Standard

Rod, Bar, Wire and Forging Stock – ASTM B 160/ ASME SB 160

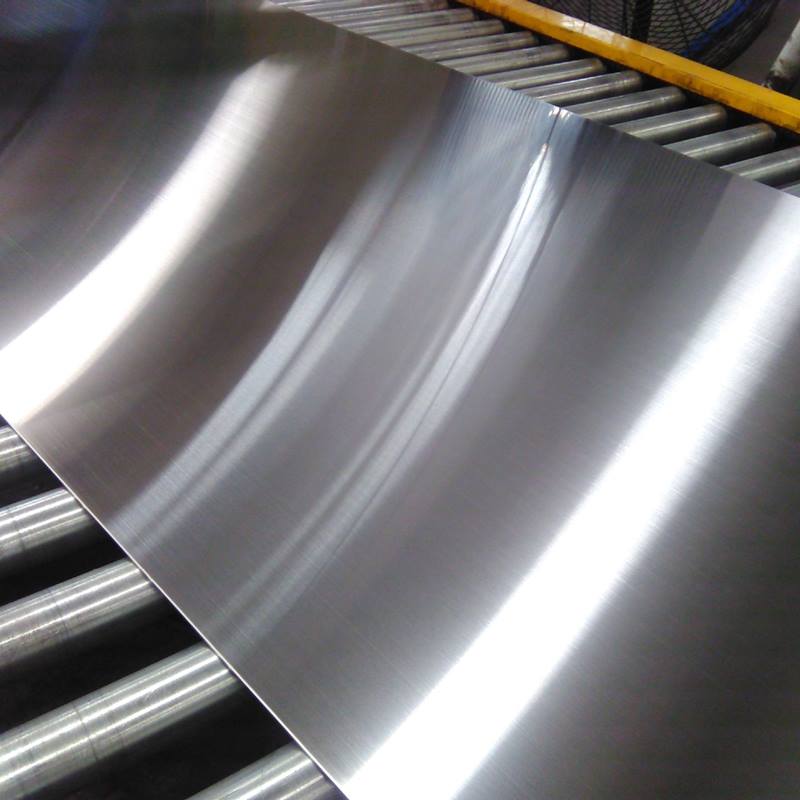

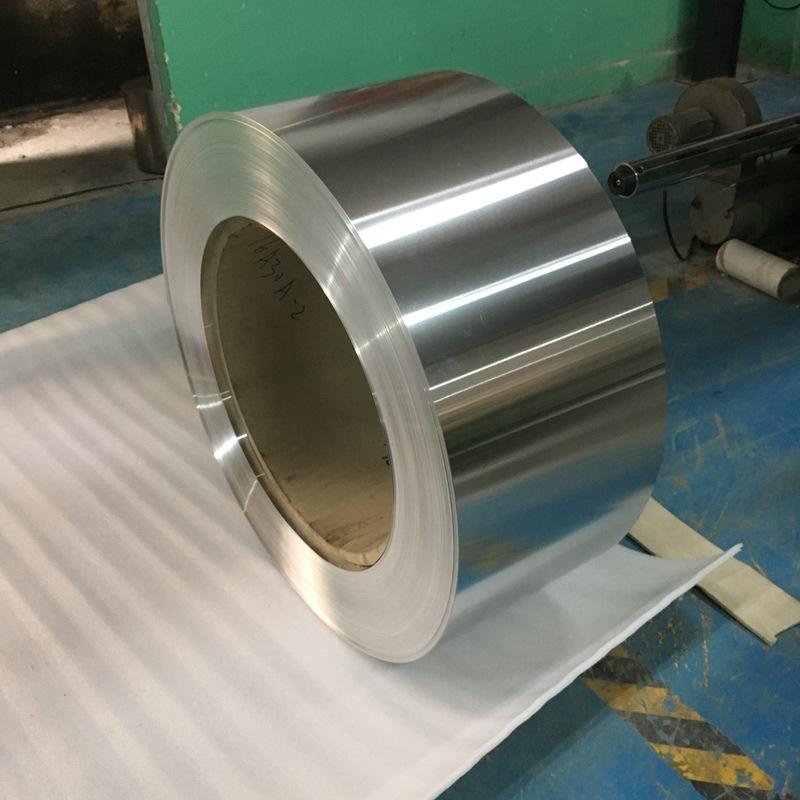

Plate, Sheet and Strip – ASTM B 162/ ASME SB 162,

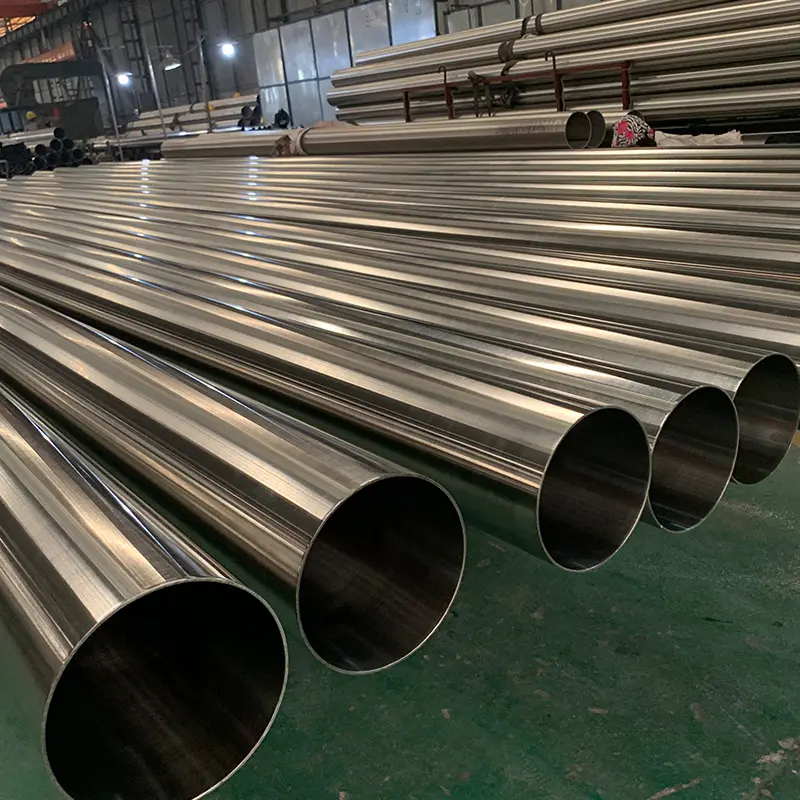

Pipe & Tube – ASTM B 161/ ASME SB161, B 163/ SB 163, B 725/ SB 725, B730/ SB 730, B 751/ SB 751, B775/SB 775, B 829/ SB 829

Fittings– ASTM B 366/ ASME SB 366

Characteristics of Nickel 600

- Heat resistance: Nickel 600 has excellent high temperature resistance, maintaining goodmechanical properties and oxidation resistance at high temperatures.

- Corrosion resistance: It has good corrosion resistance to many acidic and alkaline media, including sulfuric acid, hydrochloric acid, chloride, phosphoric acid and so on.

- Mechanical properties: Excellent tensile strength and yield strength, and can maintain good mechanical properties at high temperatures

- Welding performance: easy to weld and process, can be connected by various welding methods.