Product Detail

Chemical Composition

| Alloy | element | C | Si | Mn | S | P | Ni

|

Cr | Al | Ti | Fe | Mo | Nb |

| Alloy625 | Min | 58 | 20 | 8 | 3.15 | ||||||||

| Max | 0.1 | 0.5 | 0.5 | 0.02 | 0.02 | 23 | 0.4 | 0.4 | 5 | 10 | 4.15 | ||

| Other element | Co:1.0max | ||||||||||||

Mechanical Properties

| Aolly Status | Tensile strength

Rm Mpa Min

|

Yield strength

R P 0. 2 Mpa Min

|

Elongation

A 5 % Min

|

| annealed | 827 | 414 | 30 |

Physical Properties

| Density g/cm3 | Melting Point ℃ |

| 8.44 | 1280~1350 |

Standard

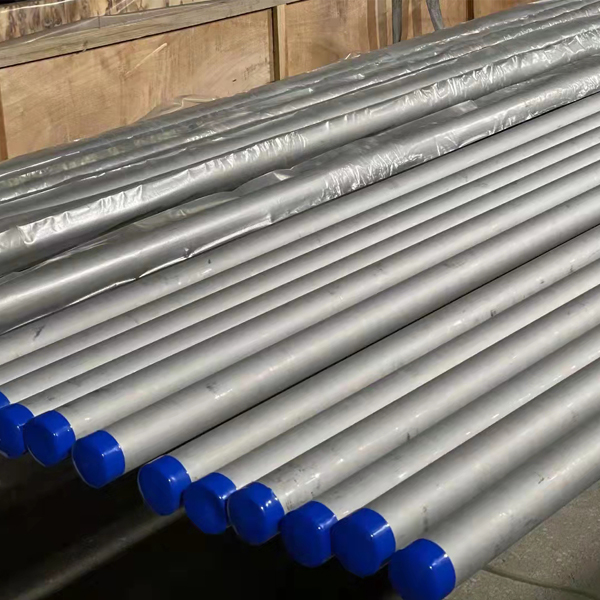

Inconel aloy Welded Pipe:ASTM B163/B516/517 /SB163/SB516/SB517

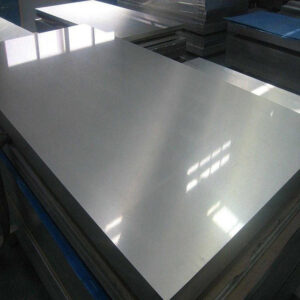

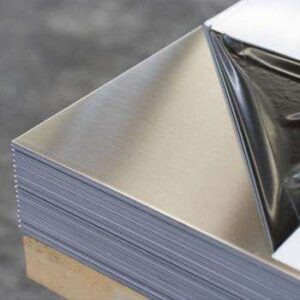

Inconel aloy Sheet and Strip:ASTM B168/SB168/5540,BS 3072

Inconel aloy Wire:ASTM B166/SB166/5687,BS 3075

Inconel aloy Bar:ASTM B166/SB166/5665,BS 3076

Characteristics of Inconel 625

- High creep-rupture strength

- Oxidation resistant to 1800° F

- Seawater pitting and crevice corrosion resistant

- Immune to chloride ion stress corrosion cracking

- Non-magnetic