Product Detail

Chemical Composition

| Alloy | element | C | Si | Mn | S | Cr | Fe | Co | Al | P | Mo | Ti |

| Alloy617 | Min | 0.05 | 20.00 | 10.00 | 0.60 | 8.00 | 0.20 | |||||

| Max | 0.1 | 0.70 | 0.70 | 0.008 | 23.00 | 2.00 | 13.00 | 1.50 | 0.012 | 10.00 | 0.60 |

Mechanical Properties

| Aolly Status | Tensile strength

Rm Mpa Min

|

Yield strength

R P 0. 2 Mpa Min

|

Elongation

A 5 % Min

|

| annealed | 550 | 690 | 15 |

Physical Properties

| Density g/cm3 | Melting Point ℃ |

| 8.4 | 1330~1380 |

Standard

Inconel aloy Welded Pipe:ASTM B163/B516/517 /SB163/SB516/SB517

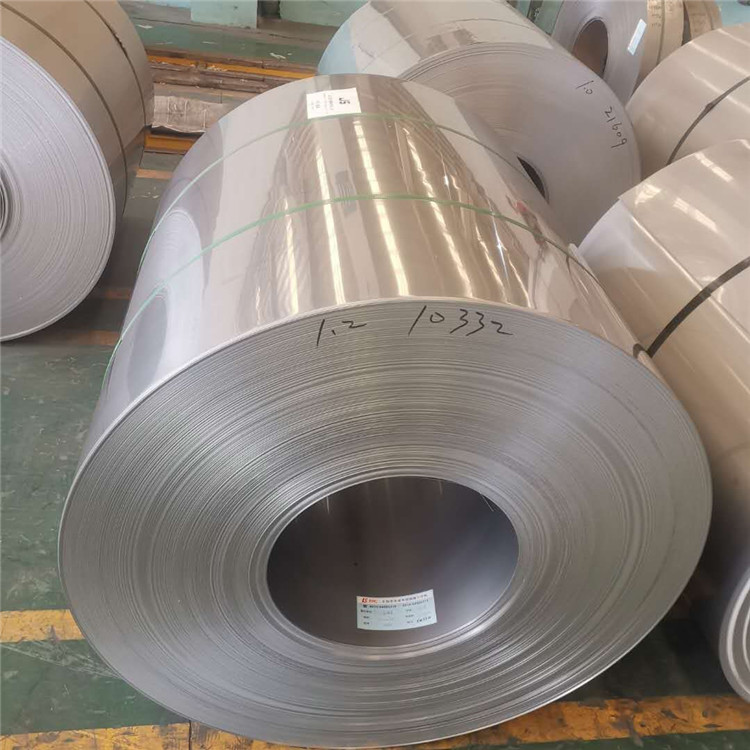

Inconel aloy Sheet and Strip:ASTM B168/SB168/5540,BS 3072

Inconel aloy Wire:ASTM B166/SB166/5687,BS 3075

Inconel aloy Bar:ASTM B166/SB166/5665,BS 3076

Characteristics of Inconel 617

- It can withstand high temperature and high pressure environments and has good corrosion resistance and oxidation resistance.

- Its excellent corrosion resistance and stress corrosion cracking resistance enable it to operate stably for a long time in harsh environments such as acidic, alkaline and salt solutions.

- It can maintain good strength and stability in high temperature environments and resist high temperature corrosion and oxidation.