Product Detail:

⇒Chemical Composition

| Alloy | Element | Cu | Ni | Pb | Fe | Zn | Mn |

| C70400 | Min | Bal. | 4.8 | 1.3 | 0.3 | ||

| Max | Bal. | 6.2 | 0.05 | 1.7 | 1.0 | 0.8 |

⇒Mechanical Properties

| Alloy Status | Tensile strength

Rm Min ksi

|

Yield strength

R P 0. 2 Min ksi

|

Elongation

in2 in., Min % |

| annealed | 38 | 12 |

⇒Physical Properties

| Density g/cms | Annealing Temperature ℃

|

Electrical Resistivity μΩ·m |

| 8.94 | 1090℃ | 0.05 |

⇒Standard

ASTM B111/B111M-2018 Standard for seamless condenser tubes in Copper and copper alloys

ASTM B 122/B 122M-2006 Standard Specification for Copper-nickel-tin alloys, Copper-nickel-zinc alloys (Nickel-Silver), and Copper-nickel alloy sheets, sheets, strips, and rolled bars

ASTM B151/B151M-2005 Standard Specification for Copper-nickel-Zinc Alloys (Nickel-Silver) and Copper-nickel bars and bars

ASTM B171/B171M-2012 Standard specification for copper alloy sheets and sheets for Pressure vessels, condensers, and heat exchangers

ASTM B466/B466M-2009 Standard Specification for seamless copper-nickel tubes

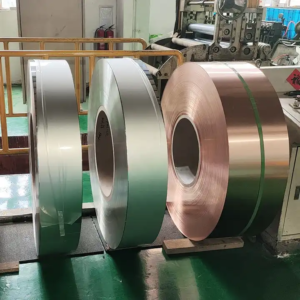

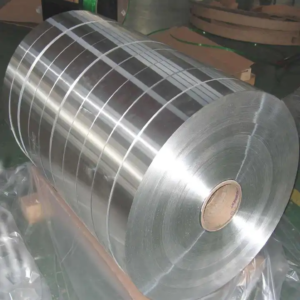

⇒Characteristics of C70400 95-5 Copper-Nickel Material

- Excellent cold processing and good hot processing.

- C70400 white copper is mainly used as casing of condenser, evaporator and heat exchanger, Marine condenser inlet system parts, etc.