Product Detail:

⇒Chemical Composition

| Alloy | Element | C | Mn | P | S | Si | Cr | Ni | N | Mo | Fe |

| S30815 | Min | 22.0 | 4.5 | 0.14 | 3.0 | Bal. | |||||

| Max | 0.03 | 2 | 0.03 | 0.02 | 1.00 | 23.0 | 6.5 | 0.20 | 3.5 | Bal. |

⇒Mechanical Properties

| Alloy Status | Tensile strength

Rm Min Mpa

|

Yield strength

R P 0. 2 Min Mpa

|

Elongation

in2 in., Min % |

Hardness(HB) | Hardness(HRB) |

| Annealed | 655 | 450 | 25 | 293 | 31 |

⇒Physical Properties

| Density g/cms | Annealing Temperature ℃

|

Thermal conductivity

100C(W/m.) |

| 7.9 | 19 |

⇒Standard

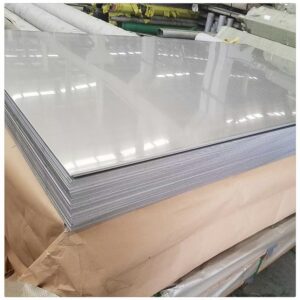

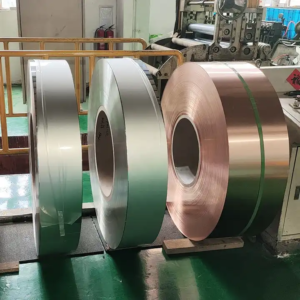

ASTM A240/ASME SA-240 Standard Specification for Chromium and Chromium-Nickel Stainless Steel PlateSheet, and Strip for Pressure Vessels and for Genera lApplications

ASTM A276 Standard Specification for Stainless Steel Bars and Shapes

ASTM A182/ASME SA-182 Standard Specification for Forged or Rolled Alloy and Stainless Steel Pipe Flanges,Forged FittingS, and Valves and Parts for High-Temperature Service

ASTM A312/ASMES A312 Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

⇒Characteristics of 2205-UNS S32205

- The yield strength is more than twice that of ordinary austenitic stainless steel

- Excellent resistance to stress corrosion cracking

- Strong corrosion resistance

- Good local corrosion resistance

- Lower linear expansion coefficient than austenitic stainless steel

- Higher energy absorption capacity