Product Detail:

⇒Chemical Composition

| Alloy | Element | C | Mn | P | S | Si | Cr | Ni | N | Mo | Cu | Fe |

| S30815 | Min | 20.0 | 23.5 | 0.18 | 6.0 | Bal. | ||||||

| Max | 0.03 | 2.0 | 0.04 | 0.03 | 1.00 | 22.0 | 25.5 | 0.25 | 7.0 | 0.75 | Bal. |

⇒Mechanical Properties

| Alloy Status | Tensile strength

Rm Min Mpa

|

Yield strength

R P 0. 2 Min Mpa

|

Elongation

in2 in., Min % |

Hardness(HB) | Hardness(HRB) |

| Annealed | 690 | 310 | 30 | 100 |

⇒Physical Properties

| Density g/cms | Annealing Temperature ℃

|

Electric Conductivity %IACS |

| 8.24 | 1320 ~1400℃ |

⇒Standard

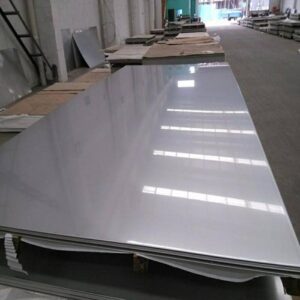

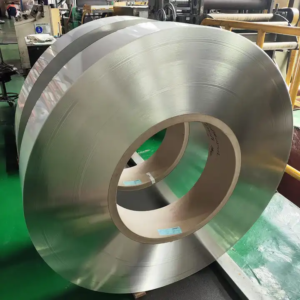

ASTM A240/ASME SA-240 Standard Specification for Chromium and Chromium-Nickel Stainless Steel PlateSheet, and Strip for Pressure Vessels and for Genera lApplications

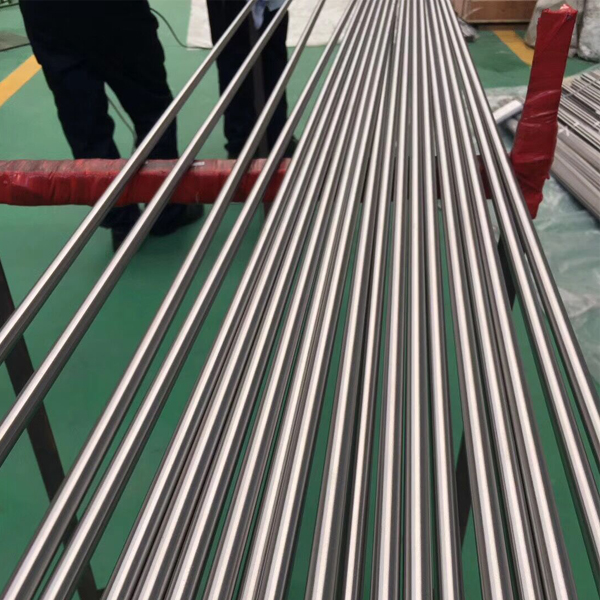

ASTM A276 Standard Specification for Stainless Steel Bars and Shapes

ASTM A182/ASME SA-182 Standard Specification for Forged or Rolled Alloy and Stainless Steel Pipe Flanges,Forged FittingS, and Valves and Parts for High-Temperature Service

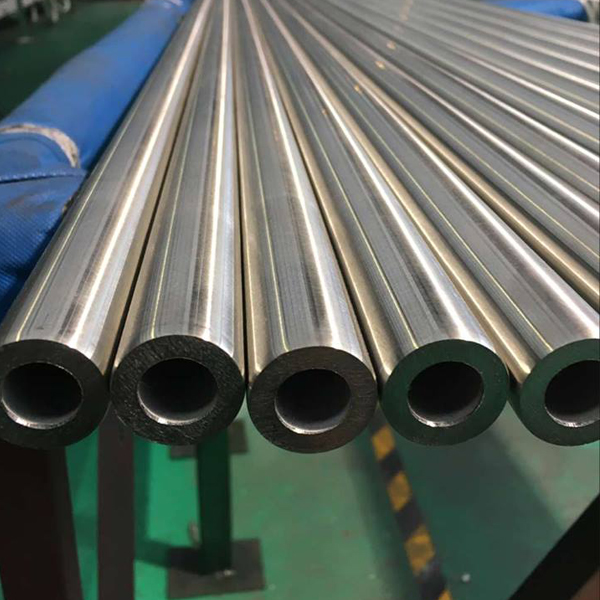

ASTM A312/ASMES A312 Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

⇒Characteristics of Al-6XN N08367 1.4501

1.Excellent resistance to chloride ion pitting and crevice corrosion

2.Corrosion resistant alloy with good cost performance

3.For other corrosion-resistant nickel-based alloys such as C-276, the corrosion resistance is similar and the cost advantage is obvious

4.It has higher tensile strength

5.Excellent material toughness and impact strength