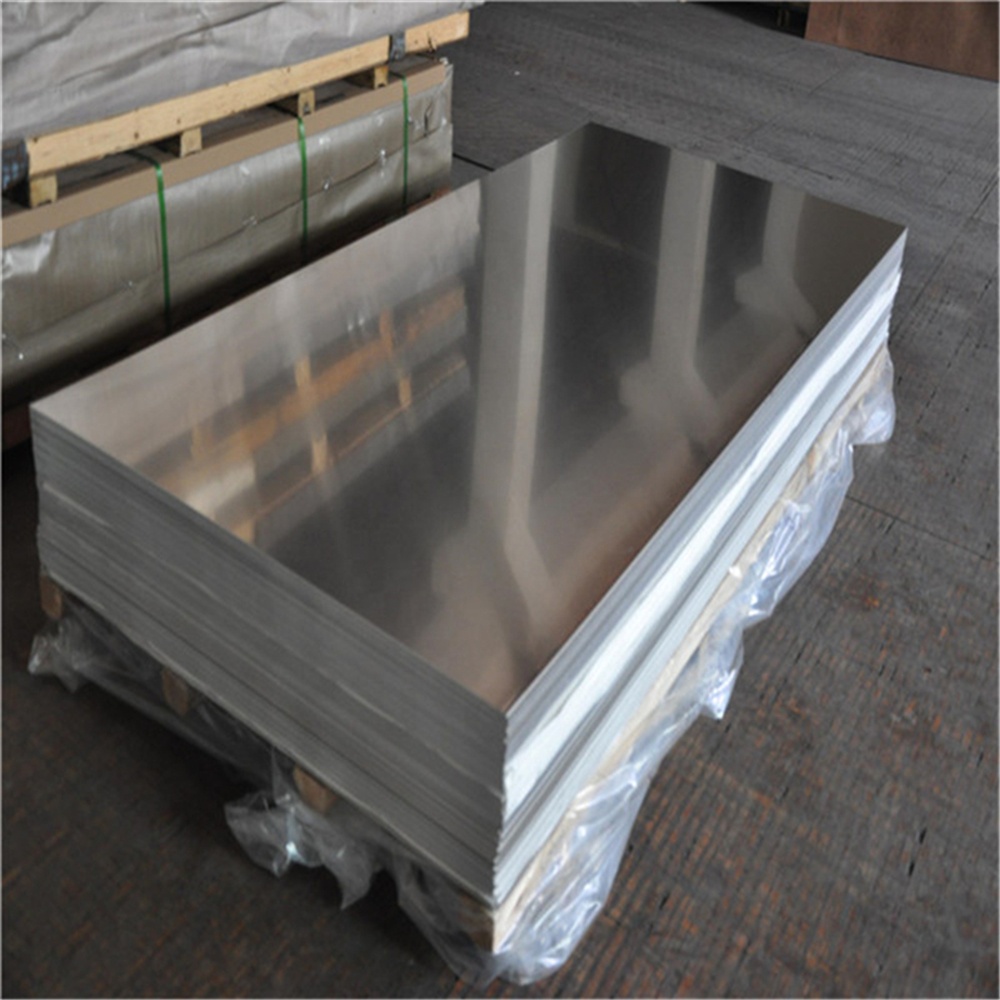

Product Detail

Chemical Composition

|

Alloy |

element | C | Si | Mn | S | P | Ni

|

Cr | Al | Ti | Fe | Nb | Mo |

|

Alloy725 |

Min |

55 |

19 |

1 |

Balance |

2.75 | 7.0 | ||||||

|

Max |

0.03 | 0.20 | 0.35 | 0.01 |

0.02 |

59 |

22.5 |

0.35 | 1.7 | 4.00 | 9.5 | ||

| Other element |

Nb:2.75~4.0 |

||||||||||||

Mechanical Properties

|

Aolly Status |

Tensile strength

Rm Mpa Min

|

Yield strength

R P 0. 2 Mpa Min

|

Elongation

A 5 % Min

|

Brinell hardness

HB Min |

| Solution | 568 | 313 | 35 |

35 |

Physical Properties

|

Density g/cm3 |

Melting Point ℃ |

| 8.20 |

1260~1340 |

Standard

Inconel aloy Welded Pipe:ASTM B163/B516/517 /SB163/SB516/SB517

Inconel aloy Sheet and Strip:ASTM B168/SB168/5540,BS 3072

Inconel aloy Wire:ASTM B166/SB166/5687,BS 3075

Inconel aloy Bar:ASTM B166/SB166/5665,BS 3076

Characteristics of Inconel 725

- Excellent corrosion resistance

- After effective heat treatment, the strength of the alloy can be greatly increased.

- After heat treatment, the ductility and tensile strength of the alloy can be greatly improved.

- Has strong anti-corrosion function