Product Detail:

Chemical Composition

|

Alloy |

element | C | Si | Mn | S | Cu | Al | Cr | Ni | Ti | Fe |

|

Nickel 800 |

Min |

0.15 |

19.0 |

50.0 |

0.15 |

39.5 |

|||||

| Max | 0.1 | 1.0 | 1.5 | 0.015 | 0.75 | 0.6 | 23.0 | 55.0 | 0.6 |

|

Mechanical Properties

|

Alloy Status |

Tensile strength Rm Min Mpa | Yield strength R P 0. 2 Min Mpa | Elongation |

| annealed | 590 | 260 |

30 |

Physical Properties

|

Density g/cm3 |

Melting Point ℃ |

| 8.0 |

1350~1400℃ |

Standard

Rod, Bar, Wire and Forging Stock – ASTM B 164 (Rod, Bar, and Wire),ASTM B 564 (Forgings)

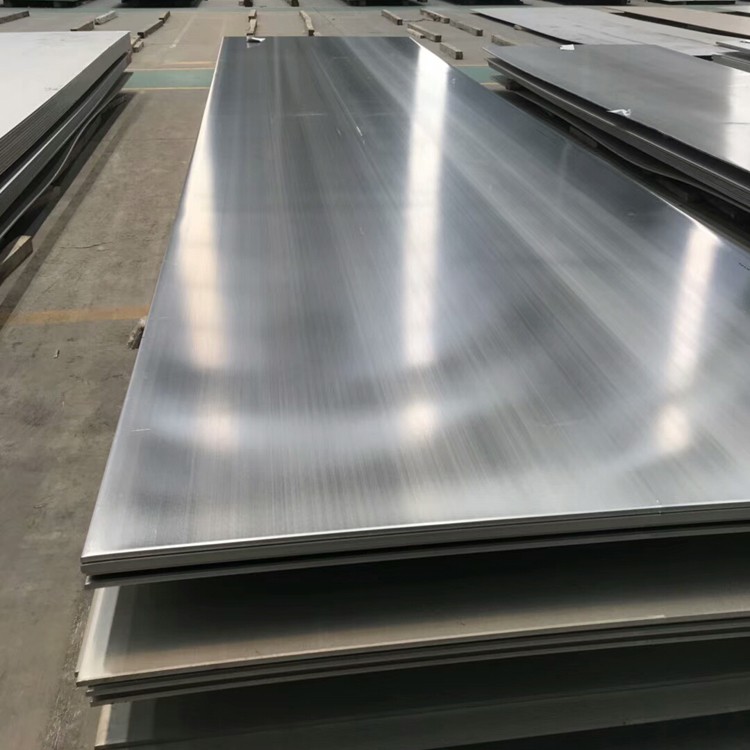

Plate, Sheet and Strip -,ASTM B 127, ASME SB 127

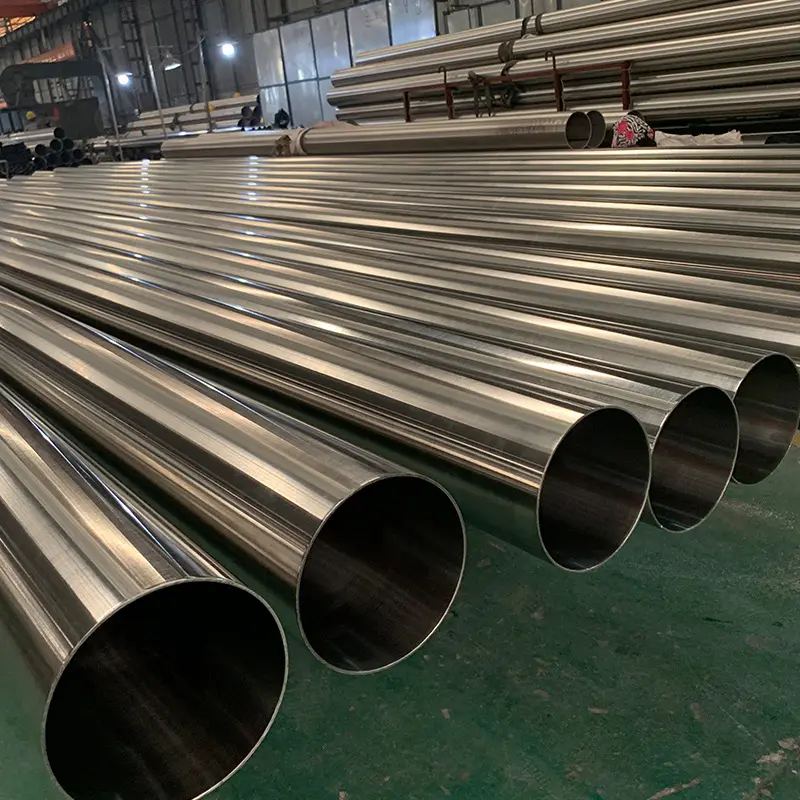

Pipe & Tube – ASTM B 165(Seamless Pipe and Tube), ASTM B 725 (Welded Pipe), ASTM B 730 (Welded Tube), ASTM B 751 (Welded Tube), ASTM B 775 (Welded Pipe), ASTM B 829(Seamless Pipe and Tube)

Welding Products – Filler Metal 60-AWS A5.14/ERNiCu-7;Welding Electrode 190-AWS A5.11/ENiCu-7.

Characteristics of Nickel 800

- Resistant to prolonged exposure to high temperatures

- Excellent resistance to yang, liu and carburizing

- Adding carbon and annealing treatments provide higher creep and fracture properties above 1100°F (600°C)

- High temperature corrosion resistance

- Easy processing by standard methods

- Recommend joining/welding with products suitable for high temperature environments

- Resistance to water corrosion at moderate temperatures